FAQ

What is chalking and how does it occur?

Chalking, loss of lustre and change of colour occur through years of weathering and influence the appearance of a coil-coated surface of building elements.

Chalking can be considerably reduced by using higher-quality coating systems. Simple polyester coatings for example chalk out much faster than a high-quality Colorcoat PRISMA® coating, which convinces by much higher UV and corrosion resistance properties.

Chalking is recognisable by the opaque whitish surface of the coatings. Slight rubbing e.g. with a finger leaves a whitish residue. This residue consists of weathered polymers and the light filling materials. Chalking must not be mixed up with bleaching. Bleaching is the loss of the colour of a pigment. Chalking however shows the destruction of the binding structure of the organic paint layer.

If paint is cleaned properly by washing off the chalking and is additionally preserved e.g. similar to car paint, then the paint surface becomes darker again, re-harmonizing with the former colour tone.

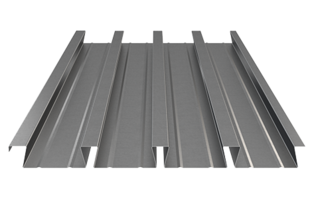

What needs to be observed when using trapezoidal profiles in swimming baths?

Particular requirements apply to steel components for the interiors of swimming baths due to the presence of high humidity combined with aggressive components (e.g. chlorine). Due to this special interior climate, we recommend the use of the Colorcoat HPS200 Ultra® coating system with a layer thickness of 200 µm (optimally on both sides). This coating system exceeds the maximum corrosion resistance class RC5 and the highest durability class for aggressive interior applications CPI5 as per EN10169.

It should also be borne in mind that, in addition to the selection of the right coating system, further structural measures are necessary, such as the sealing of the cut edges and the airtight sealing of all longitudinal and transverse joints with sealing tapes. There are different regulations for trapezoidal profiles with acoustic perforation.

Please do not hesitate and contact us. Our employees will be glad to help.

Which differences in colour tone must be accepted?

Unfortunately there is no production method without tolerances; therefore the repeated manufacture of an absolutely identical colour tone for building elements is practically impossible. The RAL system does not specify any limits, beyond which a RAL colour tone is no longer one.

The RAL register and/or the RAL cards in it do not document an exact colour tone. A RAL card can therefore not be used as a reference for differences in colour tone agreement and can only be applied as a general guide.

Identical colour tones look different on different substrates such as e.g. plastic, wood, metal, in particular also due to different roughness grades and the type and intensity of light incidence. Different application methods such as coil coating, spraying, painting or rolling, and different paint bases also play a role.

The assessment of the colour tone difference of samples with slight colour tone deviations frequently leads to different conclusions when several different assessors are involved. For the sake of clarity, the still permissible deviations must be exactly described; two samples must be agreed upon – “limit samples“ – between which the agreed design must be recognisable.

Within a closed area, a mainly uniform colour tone should be given; colour tone deviations in e.g. two surfaces meeting in a corner or “separated“ by joints, edge profiles, etc. are usually not distracting and do not represent a defect.

We point out that colour deviations in all colour tones within certain tolerance limits must be accepted when using different material batches. In case of any doubt we always recommend to have the ordered material produced from one material batch. Montana Building Systems Ltd. shall not be liable for colour differences between products from Montana amongst one another and between products from Montana and those of other manufacturers. This applies for all colours and all pre-painted products. When various products or coatings are installed with one another and need to have the same colour tone, then a selection must be made.

In the case of metallic paints and light paints that therefore do not cover well it must generally be assumed that there will be colour differences between different deliveries.

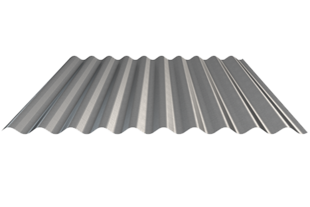

Stabilisation and reinforcement of the buildings and supports by means of trapezoidal profiles – how does it work?

Building envelope elements can be used for the stabilisation of entire buildings or individual building components. In particular, wind braces are not necessary if trapezoidal profiles are used for reinforcement via shear areas. For this, the shear areas, the trapezoidal profiles and their connections must be sufficiently dimensioned and statically verified. Shear area values for our SWISS PANEL® trapezoidal profiles are available.

Stability-endangered supports can also be stabilised by covering with trapezoidal profiles and sandwich elements.

Please do not hesitate and contact us. We will be pleased to provide you with further documents.

Where do creaking noises from building components with wooden substructures come from?

Creaking noises occur above all through sun radiation, for example during the cooling down of light metal roof or wall elements, whereby the elements themselves do not generate any noise whatsoever.

Due to the stable connection of building elements with the substructure via screws, temperature stress occurs that either shows by means of deformations, sliding displacement or, in the event of intense friction between the building element and the substructure caused by jerky displacement, by developing noises.

In multiple-shell systems such as e.g. a roof system consisting of two metal shells, thermal stress of the outer shell is diminished within the roof system via the relatively flexible intermediate Z-profile structure, such that creaking noises occur less frequently and are not as loud.

In the case of sandwich elements with a PUR/PIR core and metal cover layers, there is however, a "shear-resistant" connection between the outer and inner shell. As a result, an internal reduction of tension is only possible to a certain extent, and noises are heard more frequently. Due to the relatively low mass of the outer plate of the sandwich element, it heats up and cools down quickly, such that dilatations and/or contractions occur as a result.

Creaking noises in relatively cost-effective roof and wall systems for commercial and sports buildings cannot be reliably avoided and must therefore be considered to be normal. They do not substantiate a defect.