Our contribution

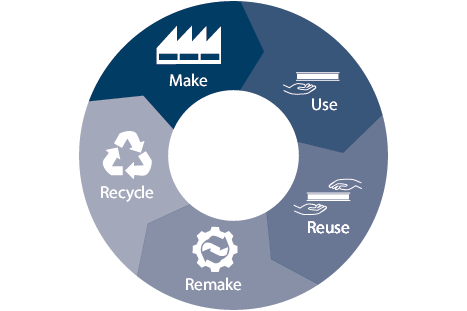

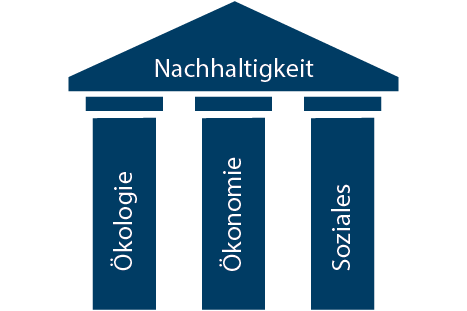

As Montana Building Systems Ltd, we bear responsibility for the sustainability of our products along the entire value-added chain with great appreciation. We implement sustainability in our products and services through the so-called "three-pillar model" of ecology, economy and social aspects.

As a SME in Switzerland, Montana Building Systems Ltd. has been committed to saving enormous amounts of C02 and optimising the energy efficiency of its plants and systems in cooperation with the Energy Agency for Industry since 2013. Every year, targeted measures are defined with the ENaW to achieve the set goals. You can find the corresponding certificate here: Climate Protection & Energy Efficiency